Message from the Chairman of the Board of Directors

Message from the Chairman of the Board of Directors

Director of Investment Management and Operational Efficiency at Rosatom State Corporation

Dear colleagues and partners,

I present to you the Integrated Annual Report of OJSC Atomenergomash for 2013. This document covers to a maximum extent the manufacturing, financial, social and environmental issues related to the activities of the Rosatom State Corporation’s Engineering Division.

In recent years, OJSC Atomenergomash has achieved significant production results and built a reputation as a reliable supplier of equipment and integrated solutions for the nuclear, thermal power, gas and petrochemical industries.

Among the major achievements of the Division in the reporting year was the launch of a full cycle of long lead equipment. An important role in this was played by the successful integration of Atommash production site in Volgodonsk, the beginning of steam generator shell production at Petrozavodskmash, and the record levels of production for steam generators at OJSC ZiO-Podolsk.

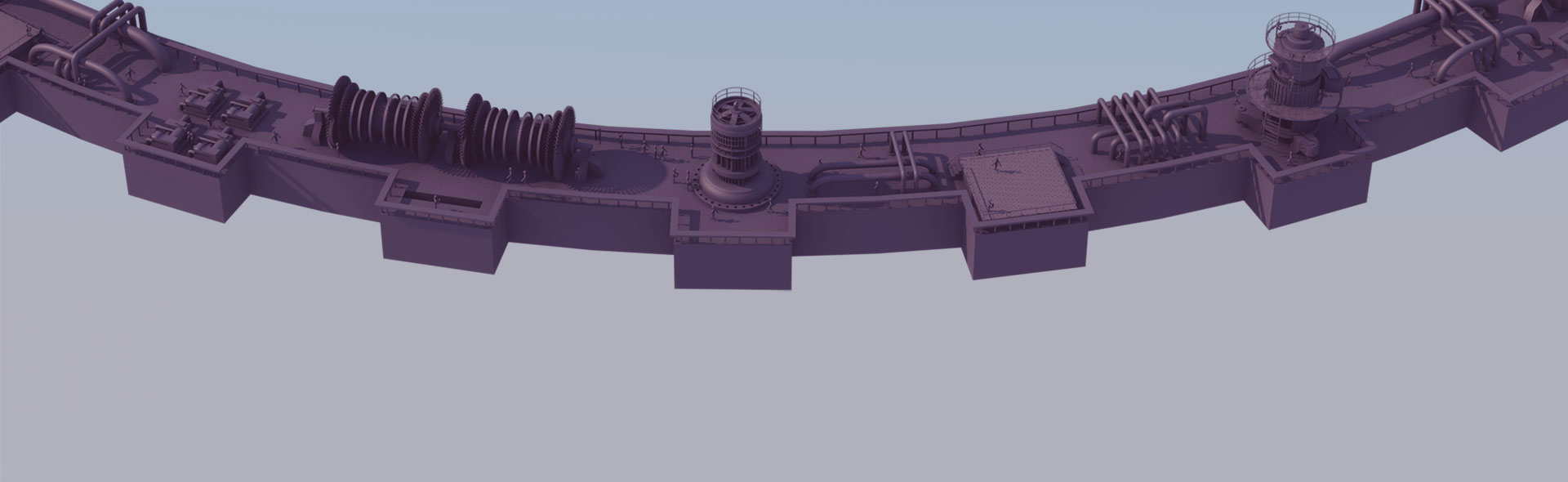

In a short period of time Rosatom has formed a company that is able to offer integrated delivery of nuclear steam supply systems (NSSS), which will enable Atomenergomash to compete with the world’s leaders in nuclear engineering in the next few years. Following the decision to start production of equipment at the turbine plant in Volgodonsk jointly with Alstom, in the foreseeable future Atomenergomash will be able to become one of the top five global companies/alliances capable of supplying both nuclear and turbine islands for NPPs.

In 2013, Atomenergomash, under the initiative of Rosatom State Corporation, has updated its strategy for the period up to 2030, which envisages transforming the Division into a high-tech diversified holding that will be stable in the long term and competitive on the global market, both in traditional nuclear areas and with new products.

In this respect, the Division has shown significant growth, having successfully started to explore the shipbuilding market, which is a new market for it. During the year, active work was carried out in other non-nuclear areas: new orders were received in the thermal power sector and for the military production complex.

Another priority in Atomenergomash’s development is focusing on innovative activities. The Division’s enterprises are successfully developing modern technological solutions and new types of equipment: from solutions for closed nuclear fuel cycle reactors to VVER reactor service life extension technologies, which have been awarded the President’s Prize. R&D expenditures in 2013 amounted to about 1.5% of revenue. By 2020, Atomenergomash plans to triple this figure.

The Division is implementing a comprehensive efficiency improvement program that is based on the implementation of the Rosatom Production System. This is evidenced by the fact that in 2013 the Division was rated the best in the all-Russian fundamental efficiency rating presented by Interfax-ERA.

On behalf of Rosatom State Corporation, let me thank Atomenergomash for its work in 2013, and its management and employees – for their commitment and professionalism. I am sure that everything that was achieved will be a powerful reserve for OJSC Atomenergomash to become a world leader in power engineering!

Message from the CEO

Dear colleagues and partners,

The central theme of the Report for 2013 is sustainable development. In this respect, the reporting year was for us a year of remarkable events and major achievements.

We have entered a new stage of development: we now have an integrated production of long lead equipment and can offer our customers a full range of services: from R&D, design, and production of castings to delivery of readymade equipment for the nuclear and thermal energy industry and related sectors.

The order book of the Engineering Division, taking into account non-sectoral orders for the last 3 years, has doubled, and by 2014 amounted to 150 billion rubles. In previous years, Atomenergomash actively increased its revenue, but in this reporting year, despite the general downturn in the engineering industry, the Company managed to maintain a level of 46 billion rubles.

In 2013, production at the Atommash production site in Volgodonsk was reestablished. Following tenders, orders for the two units of the Belarusian NPP were received. In modern history, the Belarusian NPP is the first station for which the reactor equipment is almost entirely made at Atommash.

Following the activities within the framework of the Rosatom Production System, the Division achieved record levels in production of steam generators, i.e., 9 per year. This has never happened in the history of OJSC ZiO-Podolsk, where in 2014 it is celebrating its 95th anniversary. In 2013, a new steam generator and MCP shell production for nuclear power plants, which is absolutely new, as well as production of heavy valves and new transport containers was started at Petrozavodskmash.

In 2012, large-scale modernization was completed at OJSC Energomashspetsstal. Following this, in 2013 the enterprise received large orders for Rosatom, Rolls-Royce, ArcelorMittal, Boeing, Airbus, and GE and became a certified supplier for a broad range of products for major global companies.

In 2013, thanks to cooperation, the companies of the Division won tenders and started integrated production of the RITM-200 reactor plant for the Arktika lead nuclear-powered vessel. As noted previously, we did not confine ourselves to the production of the icebreaker’s power plant and used our capabilities to produce other shipbuilding equipment and systems. The total amount of contracts already signed for the lead icebreaker amounts to about 10 billion rubles.

The foundation for the development of nuclear power engineering is work carried out by designers and planners. I would like to note the large contribution by OJSC OKB Gidropress to the work under Rosatom State Corporation projects: in Russia, Turkey, Finland, China and India. During the year, OJSC Afrikantov OKBM’s staff conducted important work to extend the life of the reactors of the existing nuclear icebreakers; large orders for the Russian Navy were received. Also, I would like to note the success in the instrument-making area. OJSC SNIIP, during the reporting year, has actively extended its order book and doubled its revenue, to almost 1 billion rubles.

In the thermal power sector, the five-year cooperation agreement with the leading European heat recovery steam generators engineering company NEM Energy has been extended. A new contract for the supply of a heat recovery steam generator for power unit No.12 at the Verkhnetagilskaya TPP was also signed. In cooperation with NEM we are already implementing projects for three stations: Novomoskovsk TPP, Yuzhnouralsk TPP-2 and Nizhnevartovsk TPP. Currently, our enterprise OJSC ZiO-Podolsk is among the three leaders in the segment of powerful boiler production in Russia.

In the gas and petrochemical segment`s we supplied equipment to OJSC Gazprom, OJSC Lukoil, and OJSC Rosneft and launched new products at Atommash. The GPI (gas and petrochemical industry) order book in 2013 has doubled compared with last year.

Great attention in Atomenergomash is paid to the implementation of innovative technologies. In 2013, a center of modern automated welding technologies started operating at OJSC NPO TsNIITMASh. The institute also designed new grades of steel which outperform imported analogues.

The growth of contracting in the thermal power, gas and petrochemical, and shipbuilding markets, as well as further improvement in quality in the nuclear segment, are the priorities for the Division’s enterprises. Taking into account the capabilities of ZiO-Podolsk, Afrikantov OKBM, SNIIP and other companies we also planned to actively extend our portfolio of defense procurement orders. In the reporting year, the companies of the Holding have fully completed the plan.

Finally, I would like to thank the employees of the Division for their professionalism, and our customers and partners for their effective mutual cooperation. The high quality standards, the focus on customers’ interests and punctuality will remain major priorities of OJSC Atomenergomash’s activities.

Geography of business

Geography of business

Interactive analysis

Interactive analysis

Print

Print

Download

Download

Favourite

Favourite